The revolution of Robot Carving and 3D Printing

3D printing and robot carving have become an essential and potentially transformative approach to the Prosthetics and Orthotics industry. They have strongly contributed to improvements in the O&P industry by enabling custom-fit, lightweight devices to be manufactured quickly, precisely and at affordable prices.

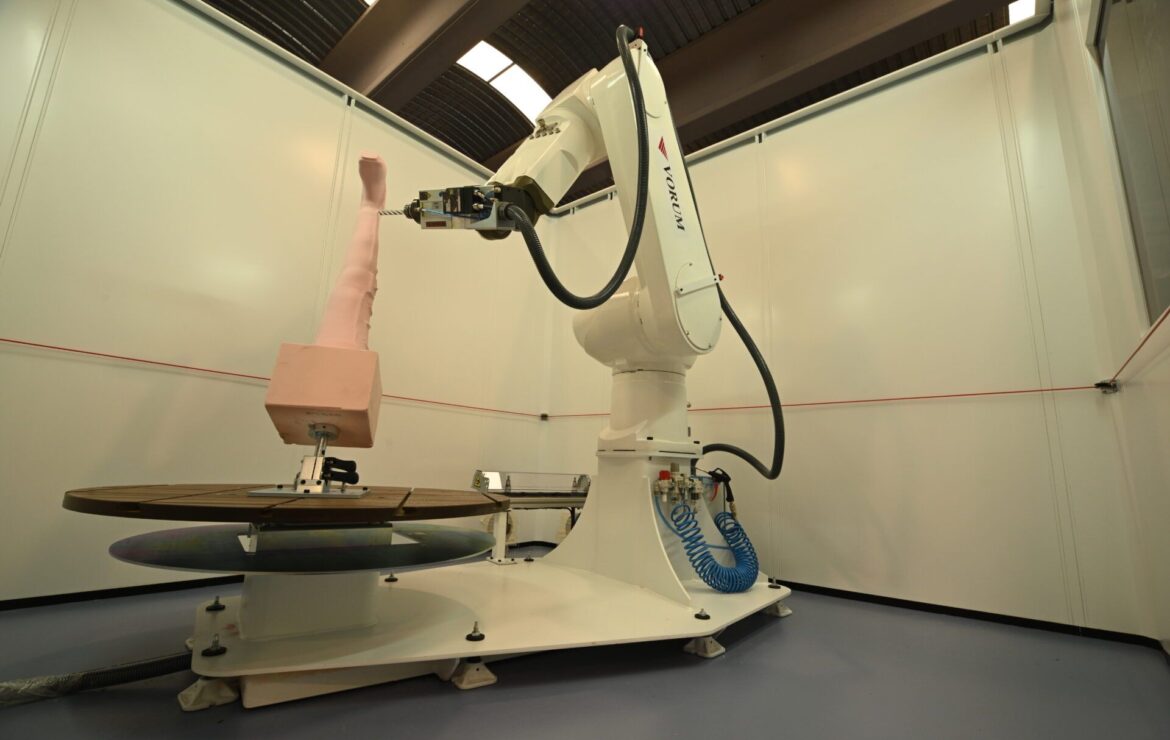

Carvers:

Advances in technology within the O&P field have allowed for the alteration of prosthetics and orthotics to fit each patient’s body and particular needs. Computer aided design allows robot carvers to create products that work as well for young soldier athletes as they do for older members of society.

Patient care is always more effective if treatment can be tailored to a particular patient. This is especially true if the treatment requires a device that fits the patient, like a prosthetic socket.

All Vorum carvers are fast, accurate, easy to operate, and built to last. They work as an integral part of the Vorum CAD/CAM solution for O&P. In minutes, a complex prosthetic or orthotic mold is ready for fabrication using Canfit. Final devices can then be milled directly on your Vorum carver.

3D printing:

3D printing essentially works by taking a digital file, cutting it into slices, and layering them on top of each other to build a product/device. This specific process is called “additive manufacturing,”. This process mimics the way nature works and is less wasteful than traditional ways of creating prosthetic and orthotic devices.

One of the main advantages of 3D printing is that it enables bespoke objects to be rapidly designed and manufactured out of variety of different materials.

Not only can 3D printing in medicine help to build these custom prostheses, but it can also make the actual prosthetic device much more comfortable and effective.

Conclusion:

There has been a quiet revolution happening for the past 15 and more years in the treatment using patient specific devices. Digital technology, 3D printing, and Robot Carvers have improved vastly to make them an everyday reality.

With 3D printing and Robot Carving, customized prosthetics are being made to suit the wearer. The printing / carving speeds up the process considerably and creates cheaper products that offer patients the same functionality as traditionally manufactured prosthetics.