Designed and built for the custom prosthetics and orthotics industry.

A reliable, automated prosthetic and orthotic carving solution for every business

Fast

Accurate

Safe

Reliable Service

3-Axis Carver

Devices

- TF, TT prosthetics

- Foam covers

- Spinals (TLSO)

- Sitting TLSOs

- AFOs, KOs, KAFOs

- Neck braces

- Cranial helmets

- Standing shells (in modules)

Materials

- Polyurethane foam

Ave. Speed (smooth finish)

- TT: 8 minutes

- AFO: 15

- TLSO: 18

4-Axis Carver

Devices

- TF, TT prosthetics

- Foam covers

- Spinals (TLSO)

- Seats (2-piece)

- AFOs, KOs, KAFOs

- Neck braces

- Cranial helmets

- Insoles

- Standing shells

Materials

- Polyurethane foam

- EVA

- Cork

Ave. Speed (smooth finish)

- TT: 9 minutes

- AFO: 18

- TLSO: 22

- Seat cushion: 25

Forma ST Carver

Devices

- TF, TT prosthetics

- Spinals (TLSO)

- Seats (2-piece)

- AFOs, KOs, KAFOs

- Neck braces

- Cranial helmets

Materials

- Polyurethane foam

- EVA

Ave. Speed (smooth finish)

- TT: 9 minutes

- AFO: 18

- TLSO: 22

- Seat cushion: 25

Robot XL

Devices

- TF, TT prosthetics

- Spinals (TLSO)

- Seats (2-piece)

- AFOs, KOs, KAFOs

- Neck braces

- Cranial helmets

- Mattresses

- Standing shells

Materials

- Polyurethane foam

- EVA

- Cork

Ave. Speed (smooth finish)

- TT: 8 minutes

- AFO: 15

- TLSO: 18

- Seat (1-piece positive): 30

- Seat (1-piece direct): 42

- Seat (2-piece direct): 35

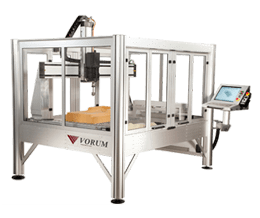

3-Axis Carving Machine

The prosthetics and orthotics industry workhorse

Vorum developed the 3-Axis Carver based on many years of input from O&P clinics, hospitals, and high volume central fabricators around the world.

Heavy duty components, precision bearings, and high quality seals make the 3-Axis Carver the most reliable and durable mold machining system available. It is a proven workhorse that delivers many years of low maintenance, accurate, trouble-free service in even the highest volume production applications.

4-Axis Carving Machine

The versatility to make direct seat cushions and insoles in addition to typical orthotic and prosthetic molds

With a rotary axis and flatbed carving surface, the 4-Axis Carving Machine is the solution to your diverse manufacturing needs for orthopedic seats and insoles in addition to a wide range of orthotic and prosthetic models.

The 4-Axis Carving Machine provides maximum versatility and efficiency. The large flatbed surface facilitates direct carving of a seat cushion or up to 8 pairs of soft insoles at one time. It enables you to produce models and devices from a variety of hard and soft materials including polyurethane, EVA, and cork.

With a small footprint - only 6.7 feet X 7.5 feet (2m x 2.6m) - the 4-Axis Carving Machine is easy to install in most facilities.

Versatile

Flexible

Efficient

Forma ST Robot Carving Machine

Combine versatility with a small footprint

Forma ST gives any-sized practice the opportunity to consider inhouse digital manufacturing without worrying about space. The machine is fully enclosed with the connections to implement a vacuum system to make cleaning easy.

Without compromising capacity or detail, this machine is capable of precision milling of a variety of custom O&P devices. The robust robotic arm enables it to work in high-volume production settings.

Forma ST can be further enhanced with modular components for greater functionality. From carving custom seats to cutting out plastic trimlines, this system has the essential tools to make in-house fabrication easier and faster.

Compact

Quiet

Modular

Robot 7-Axis Carving Machine

The fastest, most versatile prosthetics and orthotics carving solution

The Vorum 7-Axis Robot Carving Machines are the only robots in the market designed specifically for the Orthotics and Prosthetics industry. They are precise, able to carve any material, and the fastest available.

Vorum provides a simple user interface with a user-friendly touch screen resulting in the best carving solution in the market.

Vorum’s Robotic Carvers provide you with 7 Axis capabilities in a compact, sturdy design. Each dust-resistant carver comes fully enclosed in a secured polycarbonate enclosure with built-in vacuum ducting for fast cleanup.