Spinal Technology

SurePath goal achieved by improving Canfit Modifications by more than 30%

Spinal Technology has been using the Vorum solution since 2008 when they purchased Vorum’s Canfit Software. Now 16 years later Spinal Technology is still using an end-to-end Vorum solution.

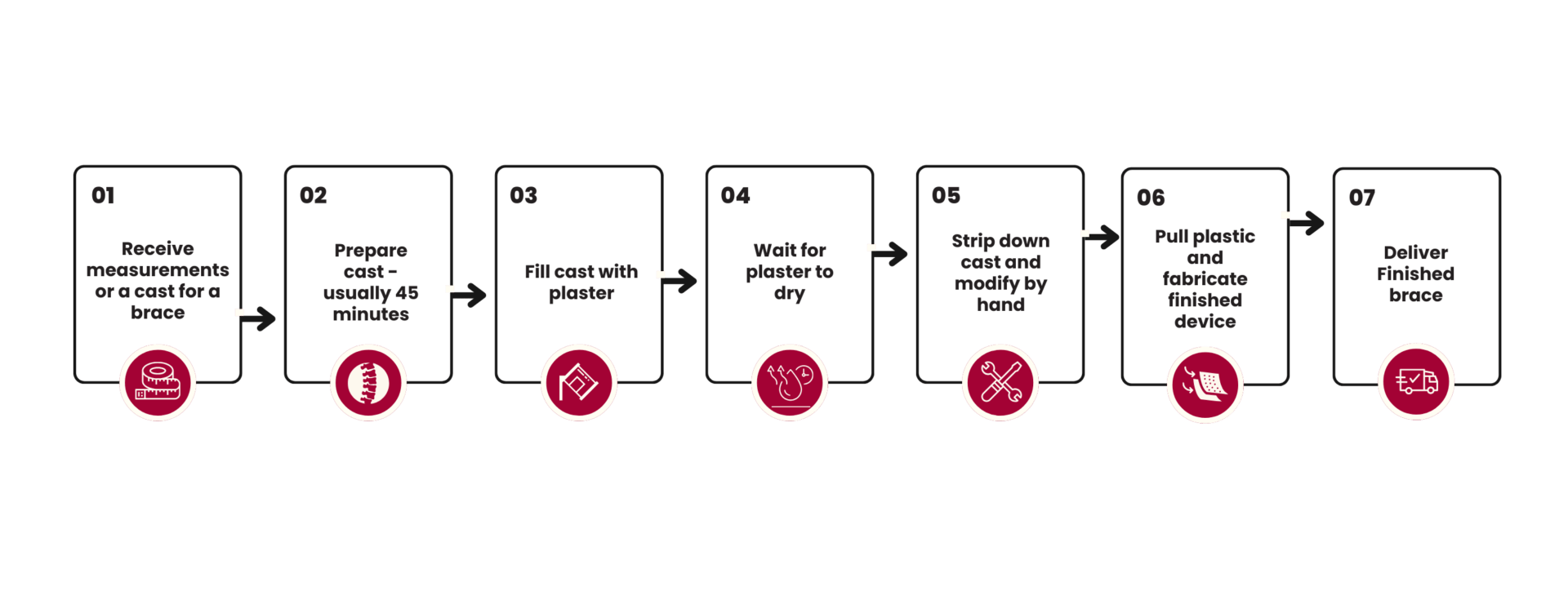

Before using Vorum products, Spinal Technology used a mixture of dated CAD software and plaster. This process was slow, and plaster was very heavy and difficult to manage. Having casts shipped could take several days and when they arrived there was still a lot of work to do.

Spinal Technology made the decision to purchase Vorum’s Canfit Design software in 2008 because the demands and needs in the O&P industry were increasing, and it was clear to them that they needed to implement a high functioning Computer Aided Design software to help with their workflow. Spinal Technology was expanding, and they needed the equipment and software that would do more for them and be more efficient.

The process for Spinal Technology before using Vorum went like this:

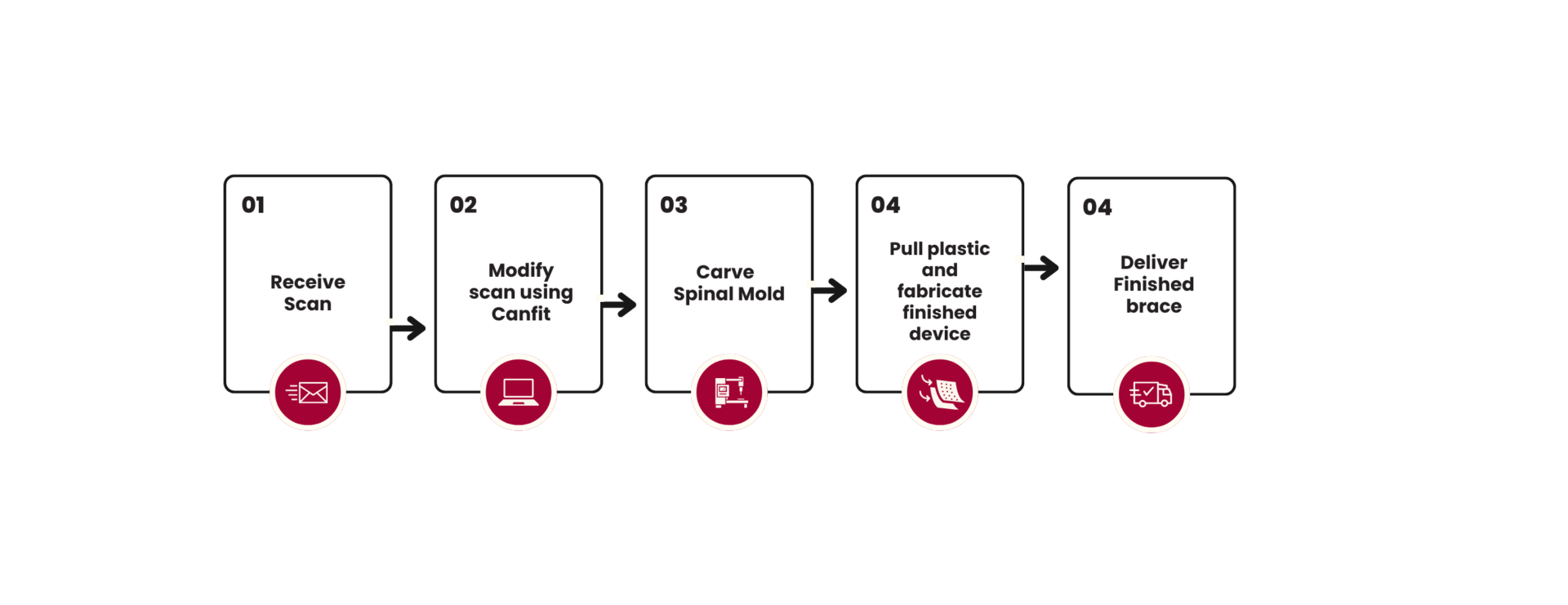

This is Spinal Technology’s workflow now:

The impact of implementing this technology was noticed immediately.

“We can now scan in a matter of minutes and an email is sent straight away. You don’t have to wait three days for the cast to be delivered and modified, we can now modify scans much sooner.” – Jonathan Taylor, Director of Clinical Development and Education, Spinal Technology

Making the move to a digital solution can seem scary, however, once Spinal Technology made this move, they never looked back. Jonathan explained about how the “advantages of implementing Vorum Technology for Spinal Technology are numerous”. Firstly, it has made the workflow much more efficient. It is easier and quicker to send and share scans, and they carve their modified positive molds on site which has increased their productivity significantly. Jonathan also expressed how technology gives him and his team more control over the modifications that they are making. They’re also grateful to be able to undo steps that they’ve taken to reduce the risk of error.

Finally, one of the main advantages to Spinal Technology has been the ability to save templates and previous work, not only has this saved them time but also a lot of physical space as now these measurements are stored digitally.

“We really saw the benefits very quickly. We have about 7000 molds between our two facilities that used to be plaster sitting on shelves. Once we had the technology, we started scanning these molds which are now stored digitally. This has sped up our workflow significantly” – Jonathan

Jonathan also pointed out that the workflow is now much safer. The plaster molds previously used were very heavy, it could sometimes take weeks for each mold to dry after filling them in. Some of the bigger molds that Spinal Technology would have worked with would need a forklift to help move them. Now, the Vorum carvers allow Spinal Technology to carve using much lighter Foam blocks which have made the workflow much safer and more efficient.

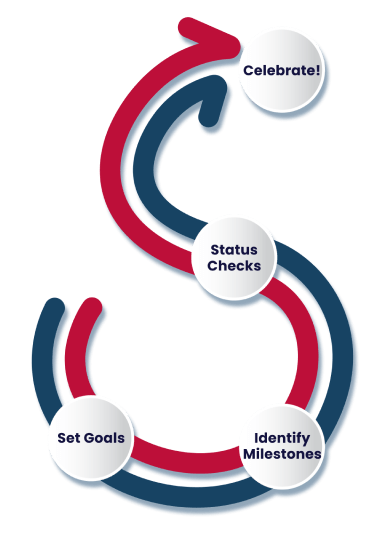

Part of Vorum’s commitment to our customers is to set and reach your business goals through our SurePath solution. One of Spinal Technology’s SurePath goals in 2022 was to streamline their Canfit Design process. At the time, there were a few different processes for modifying scans and their aim was to streamline the process in order to increase efficiency.

Vorum worked closely with Spinal Technology to help them meet this goal. Vorum took a close look at the steps that Spinal Technology would go through to complete their modifications. We then worked closely with Spinal Technology to implement macros into their workflow to streamline their modification process. “We started down that path of learning to use some of the more advanced tools with macros and overlays. We also just looked at it from a different perspective so the amount of work that we were putting in reduced greatly” – Jonathan.

Through the combined effort of Spinal Technology and Vorum, this SurePath goal was completed and now Jonathan explained that they have “reduced our modification times by at least 30%”

In addition to implementing the Canfit software and Vorum carvers into their workflow, Spinal Technology is also an advocate for our Luma 3D scanner. “I have found capabilities with the Luma scanner that I don’t think I could have accomplished with other scanners” – Jonathan.

Jonathan explained that he recently travelled to Guatemala with the Luma scanner. He was scanning patients who were non-ambulatory and lying in a bed. “I could just use the extension cord and hold it with my hand and scan the patient, which was a lot easier than trying to hold a tablet or an iPad. I've found it invaluable; we get great quality scans and it's quick.” – Jonathan.

What’s next for Spinal Technology and Vorum? Spinal Technology is looking forward to expanding the Luma 3D scanner into more operations and to their customers. Vorum and Spinal Technology are looking forward to working together in the future with the overall aim of improving patient outcomes.

At a Glance

Spinal Technology is the global leader in the design and custom fabrication of Spinal Orthoses, for the stabilization, immobilization, and the correction of various abnormalities of the spine. Specializing in the treatment of Adolescent Idiopathic Scoliosis, we employ the latest technologies and methods for treating each and every patient.

Reduced Canfit Modification times by more than 30%

Modification process streamlined

Significantly improved workflow

7000 previous plaster molds, now stored digitally