Boost productivity. Eliminate plaster. Make better-fitting prosthetics and orthotics.

CAD/CAM and 3D Printing Solutions for Orthotics and Prosthetics Providers

For many years, the custom fitting of orthotic and prosthetic (O&P) devices involved a manual plaster casting process that was slow, messy, and uncomfortable for the patient. Modern Computer-aided Design and Manufacturing (CAD/CAM) replaces plasterwork with a digital solution that is much faster, more accurate, more pleasant for patients, and safer for clinicians.

01

Scan your patient's shape

Non-contact 3D optical scanners capture your patient’s shape much faster and more accurately than plaster casts - without mess and discomfort.

02

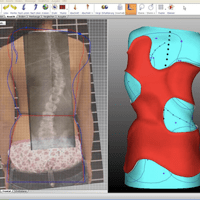

Modify the form

Computer-based 3D design software tools let you quickly apply anatomical corrections to the scanned shape to create the desired form.

03

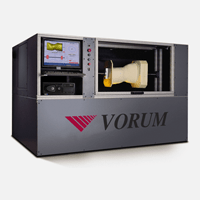

Fabricate the mold or 3D print

A high speed carver automatically machines an accurate, lightweight foam mold, or a 3D printer fabricates the device directly.

Grow your business with Vorum

Boost productivity by up to 600%.

Increase device turnaround time, allowing you to see more patients.

Eliminate plaster room bottlenecks and safety hazards.

Easily share detailed patient shapes and treatment history with partners and payers.

Create a repeatable and measurable workflow.